-

供熱管道保溫的必要性及常用保溫方法

供熱管道的保溫(wen)材料(liao)應(ying)具有耐熱性、阻燃(ran)性、低熱導率(lv)、低吸(xi)濕率(lv)和無腐蝕性。為(wei)了(le)加(jia)強機(ji)械強度(du),一(yi)般(ban)做成瓦塊,常用(yong)巖(yan)棉(mian)管殼(ke);超(chao)細玻璃棉(mian)管殼(ke)、聚(ju)氨酯醋泡瓦;珍珠巖(yan)瓦和其他隔熱材料(liao)。 ??保溫(wen)層的厚(hou)度(du)應(ying)合理、經濟地選擇。如果保溫(wen)層太薄,熱量(liang)損失會(hui)增(zeng)加(jia);如果保溫(wen)層太厚(hou),增(zeng)加(jia)散熱表面積也(ye)會(hui)增(zeng)加(jia)熱量(liang)損失。保溫(wen)層的厚(hou)度(du)一(yi)般(ban)應(ying)根據保溫(wen)材料(liao)的性能、熱媒的溫(wen)度(du)等(deng)因素來確定,常用(yong)的厚(hou)度(du)為(wei)40~50㎜。

了解詳情 -

鐵皮保溫施工有什么經濟效益?

鐵皮(pi)保溫施工需要(yao)的時間比(bi)較長,所以要(yao)特別(bie)注意這類管道或(huo)者(zhe)設(she)備的保溫效果。由于他的工作量很大(da),不(bu)(bu)僅要(yao)保持管壁的溫度,還要(yao)避(bi)免它們在操作中(zhong)受到損(sun)傷。如果保溫對(dui)象(xiang)每天的作業不(bu)(bu)多,那么可以簡(jian)單的保養一下(xia),不(bu)(bu)需要(yao)精(jing)心(xin)保養。

了解詳情 -

常規不銹鋼風管加工流程是怎樣的?

下料應(ying)嚴(yan)格按設計單(dan)線圖進(jin)行,切(qie)割前材料尺寸應(ying)仔細(xi)核對(dui)。數控剪板機(ji)直條下料(誤差正負(fu)0.1mm)

了解詳情 -

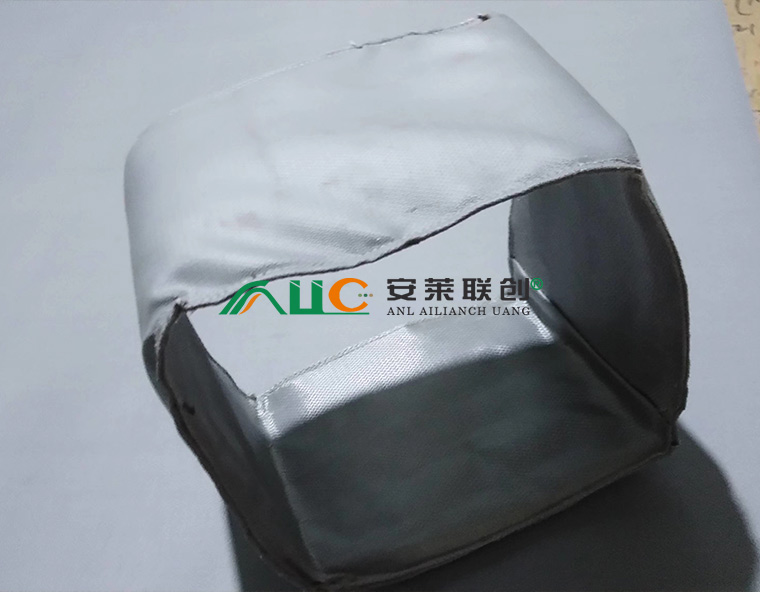

鐵皮保溫施工方法和鐵皮的保溫作用有哪些?

鐵皮(pi)保溫施工(gong)(gong)(gong)(gong)(gong)的方法可以(yi)分(fen)為(wei)三個(ge)(ge)(ge)步驟,它(ta)們(men)分(fen)別(bie)是(shi)質(zhi)(zhi)保體系、施工(gong)(gong)(gong)(gong)(gong)分(fen)段(duan)驗(yan)(yan)收(shou)以(yi)及(ji)施工(gong)(gong)(gong)(gong)(gong)工(gong)(gong)(gong)(gong)(gong)序(xu)(xu)。其中質(zhi)(zhi)保體系應為(wei)一個(ge)(ge)(ge)步驟。所謂的質(zhi)(zhi)保體系就是(shi)成立一個(ge)(ge)(ge)質(zhi)(zhi)檢小(xiao)組(zu)(zu),并由(you)他們(men)負責(ze)對工(gong)(gong)(gong)(gong)(gong)程的各階段(duan)進行(xing)質(zhi)(zhi)量(liang)檢查(cha)。同(tong)時值得注意的是(shi)這(zhe)個(ge)(ge)(ge)質(zhi)(zhi)檢小(xiao)組(zu)(zu)也就是(shi)專門設定的工(gong)(gong)(gong)(gong)(gong)程質(zhi)(zhi)量(liang)檢驗(yan)(yan)人員;第(di)二步是(shi)進行(xing)施工(gong)(gong)(gong)(gong)(gong)分(fen)段(duan)驗(yan)(yan)收(shou)。當然這(zhe)個(ge)(ge)(ge)分(fen)段(duan)驗(yan)(yan)收(shou)還是(shi)由(you)質(zhi)(zhi)檢人員負責(ze)的;第(di)三步也就是(shi)z后一個(ge)(ge)(ge)步驟——施工(gong)(gong)(gong)(gong)(gong)工(gong)(gong)(gong)(gong)(gong)序(xu)(xu)。 鐵皮(pi)保溫施工(gong)(gong)(gong)(gong)(gong)工(gong)(gong)(gong)(gong)(gong)序(xu)(xu)是(shi)由(you)四部(bu)分(fen)組(zu)(zu)成的,它(ta)們(men)依次(ci)為(wei)搭建腳手(shou)架、安(an)(an)裝(zhuang)保溫材料、安(an)(an)裝(zhuang)鐵皮(pi)以(yi)及(ji)質(zhi)(zhi)量(liang)驗(yan)(yan)收(shou)。

了解詳情

微信號:

微信號:

全國服務熱線

全國服務熱線

布箔膠帶

布箔膠帶 白帆布

白帆布 微信咨詢

微信咨詢  添加微信

添加微信

聯系我們

聯系我們

電話咨詢

電話咨詢